The car manufacturer is testing the robots to see if it can deliver parts to production lines.Continue reading

Audi Hungaria has introduced new technologies in engine production, the Győr-based (northwestern Hungary) company said on Friday, writes Világgazdaság.

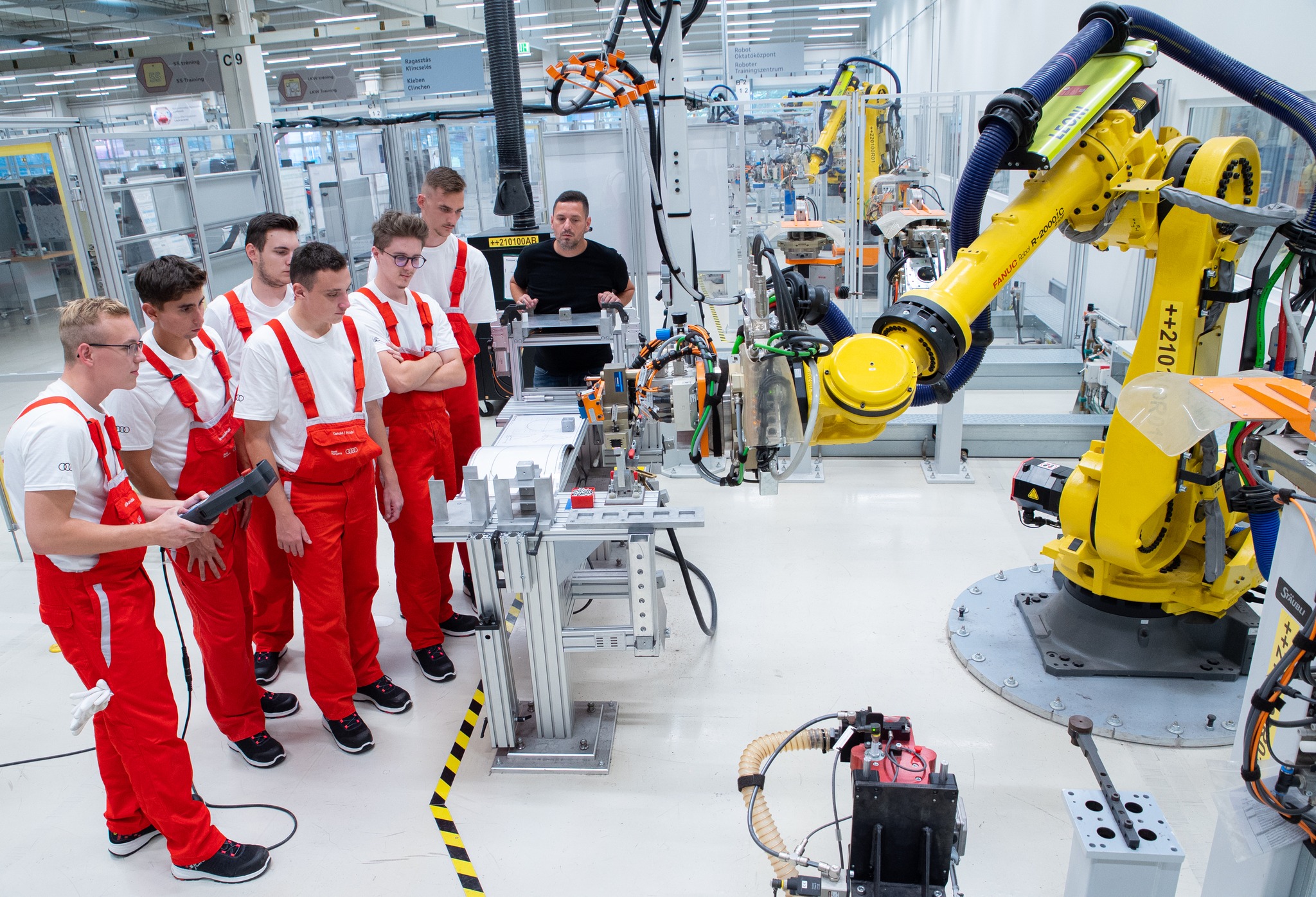

In the transformation of the automotive industry, modernization of the technologies used in production plays an important role alongside the continuous development of staff skills. The company announced that Audi Hungaria will, among other things, increase the efficiency of production through automation technologies, which will help Audi Hungaria to remain competitive by increasing the cost-effectiveness of production.

A recent development in the field of automation is the installation of a robotic station that places the injectors in the cylinder head in the four-cylinder petrol engine.

Each injector is inspected by camera and photographed before insertion. Around 680 people work on these production lines, and a new R4 Otto TSI EVO2 engine leaves the production line every 30 seconds or so. Thanks to the project, one manual workstation has been automated, reducing the number of ergonomically unfavorable workstations.

In addition, a previously semi-automated workstation has been automated by the experts in Győr: a manipulator, a robot, and a screwing station work in one cell at the station, handling 8,000 spark plugs per day, and the spark plugs are inserted into the three- and four-cylinder engines in an automated process.

Audi Hungaria is one of the largest engine manufacturers in the world. In 2023, the company’s employees produced a total of 1,660,425 vehicle powertrains, of which 114,058 were electric. The company started series production of the Premium Platform Electric (PPE) electric engine family in 2023, and will continue to prepare for the production of MEB ECO powertrains in 2024.

Headquartered in Győr, Audi Hungaria is a member of the Audi Group and the central engine supplier to the Audi and Volkswagen Groups.

It produces around 1.7 million power units a year,

including electric engines. The Audi Q3 and Q3 Sportback models, which are also available with electric powertrains, are produced in Győr.

Audi Q3 Sportback. Photo via Facebook/Audi Magyarország

Audi Hungaria supplies a number of aluminum body components for various Volkswagen Group brands and is increasingly involved in development activities – powertrain and vehicle development. The company provides a wide range of services for the entire Volkswagen Group, mainly in the fields of technical development, finance, IT, and procurement.

Audi Hungaria is one of Hungary’s biggest companies in terms of turnover, one of the country’s largest exporters, and the largest investor in the Hungarian automotive industry. The company has been carbon-neutral since 2020, and is the largest employer in the region with around 12,000 employees.

Via Világgazdaság; Featured image via Facebook/Audi Hungária Győr