LG Magna will manufacture various equipment and components for electric cars and electric motors, on-board chargers, and inverters.Continue reading

In the long term, Hungary could be a winner from the mounting problems of the German economy, as there are growing signs that Europe’s economic engine will suffer in the coming years if it cannot deal with the challenges of the Russian gas cut-off and the green transition, Világgazdaság reports.

The German economy has been struggling with a number of problems recently, with the sector already producing low figures since the end of last year. Although inflation has now fallen and growth could return in the fourth quarter, the long-term outlook is still not perfect. Germany now risks losing its edge in international markets because of the accumulated problems.

Against this background, it is no coincidence that German business leaders are increasingly open in their criticism of the official economic policy stance and that many of them are planning to outsource production.

Most recently, a report published at the end of August showed that 52% of German companies said that the switch to clean energy would have a bad or very bad impact on their competitiveness. Moreover, 32% of manufacturers are considering or have already started to move production abroad.

According to Péter Virovácz, senior analyst at ING Bank, Germany is not ready for the 21st century. However, the problem is not new: for a very long time, Germany has been under the spell of a balanced budget, while firms have been able to operate with a very low cost structure. Then came the energy crisis, making the economic structure unsustainable. “We used to say that if something was high-tech, it must have come from Germany, but that is no longer true,” the analyst pointed out.

The COVID pandemic and the disruption of supply chains have also played a role in the weakening of German exports, but an even bigger problem is that while Chinese customers used to buy German products, this is no longer true.

China can now produce much larger quantities and perhaps better quality consumer durables, so demand for German manufactured goods has also fallen.

In addition, Virovácz noted that domestic demand stimulation as a tool is also lacking, with the latest program announced by Chancellor Scholz’s cabinet amounting to only 0.2% of the GDP.

Hungary, however, could benefit from the weak performance of the German economy, specifically from the emigration of German firms.

Zoltán Török, senior analyst at Raiffeisen Bank, pointed out that Hungary is very unhappy about the weakness of the German economy, which he does not see turning around just yet. However, the issue is complex: on the one hand, there is an energy crisis, causing investment to lag and production to fall, and on the other, German companies are clearly looking elsewhere. Hence, energy-intensive companies are investing mainly in America, while others are investing in Central Eastern Europe, and that is why we can still benefit from this.

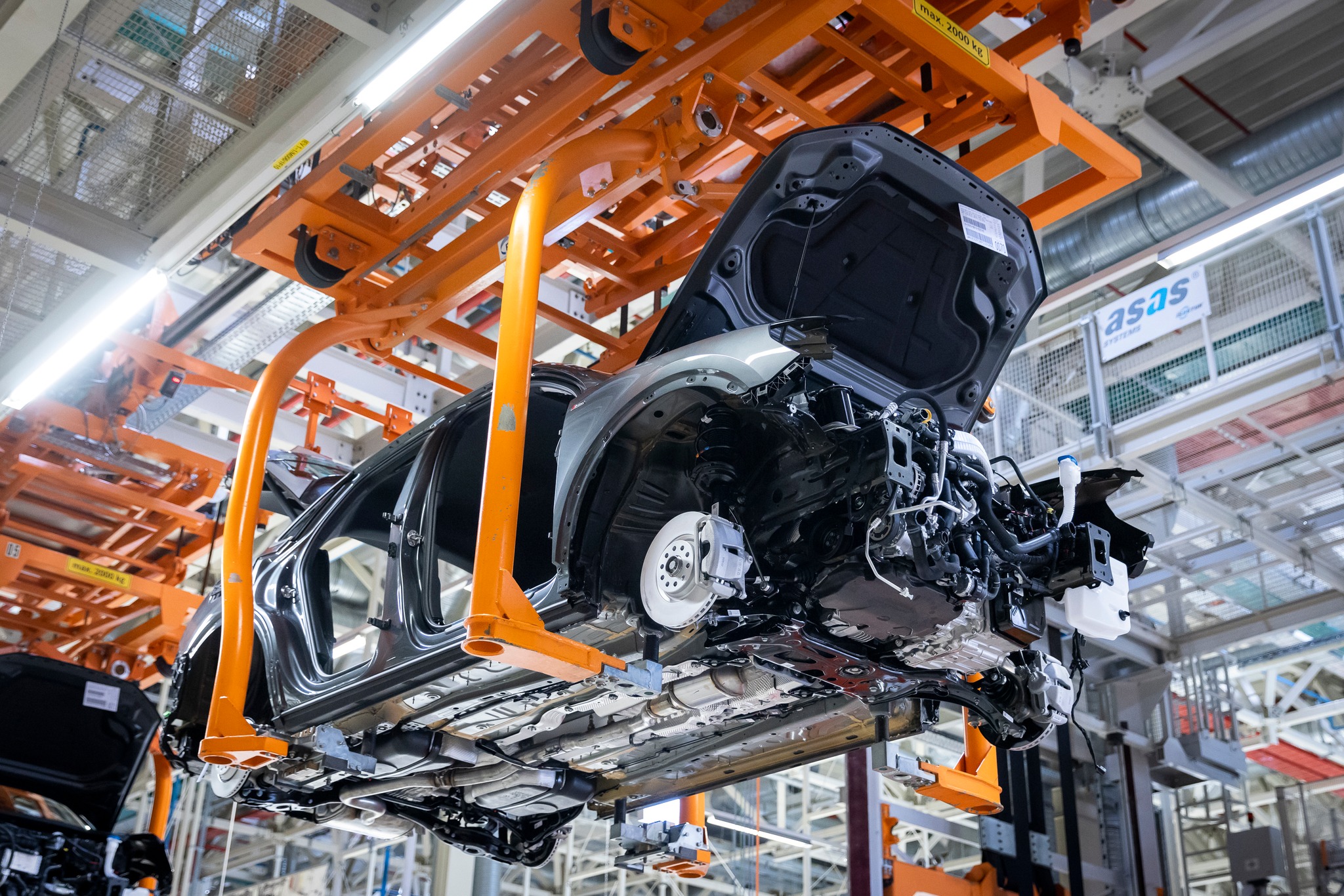

“If you look at the automotive industry alone, the production volume of German car manufacturers in Hungary is increasing,” he pointed out, adding that if BMW starts production from 2025, it will add to this.

The BMW factory’s construction site in Debrecen. Photo:Facebook/BMW Group Gyár Debrecen

Virovácz nuanced the picture by saying that

if German exports are bad, it could also be a sign that there is a problem with global demand, and we cannot disconnect ourselves from this. While capacity-increasing investments can mask this for a while, we could be entering an era of industrial recession.

Analysts agree that Europe and European car manufacturers are clearly at a disadvantage in the electric transition compared to China and America, as reflected by the fact that an electric Volkswagen costs as much as a Tesla, while not having the same parameters. Nevertheless, Török believes that this is a situation that can be overcome, that it is not a foregone conclusion, and that there is a knowledge and technical capability that can mitigate this gap. “It would be a shame to bury the German car industry just yet,” noted the Raiffeisen Bank senior analyst.

Featured photo via Pixabay