Minister Péter Szijjártó held a press conference on the progression of the project.Continue reading

The first major installation of the Paks II project, the core catcher of Unit 5, is complete. The 730-ton piece will arrive at the Paks site by waterway. The installation is a third-generation special safety-enhancing solution developed by Russian engineers, Magyar Építők reports.

The VVER-1200 unit being built at Paks will be equipped with several passive safety systems. The common feature of these units is that they do not require human intervention and external energy sources to operate, and their function is ensured by simple physical processes, the portal writes. They replace the active safety systems in the event of a failure and ensure the cooling of the active zone and the integrity of the containment building.

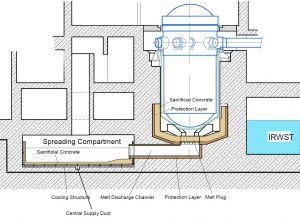

The core catcher is a special tank located under the reactor vessel and capable of containing the zone melt in the event of a breach.

It helps to reduce hydrogen evolution and the release of radioactive material into the environment. The vessel contains a fusion charge containing alumina and iron oxide, which when mixed with the zone melt, reduces the specific heat of the melt.

Diagram of a core catcher. Photo: Wikipedia

The installation is a special safety enhancement for the improved third generation VVER-1200 units. The innovative unit, developed by Russian engineers, will be located under the reactor vessel and will be able to contain the zone melt in case of damage.

A major milestone in the history of the Paks II project is the completion of the Unit 5 core catcher, the largest piece of equipment in the plant, weighing more than 730 tons and over 15 meters high (the size of a four-story building.)

The licensing and production of the special tank for the localization of the zone melt is the result of years of work. The process has generated almost 35,000 pages of documentation. The production licensing documentation for the Hungarian Atomic Energy Authority amounted to 15,000 pages. This was checked by Paks II engineers in several rounds with the involvement of external experts before being made available to the authority. During standard verification, the applicable standards were compared with national and international requirements.

Just like the design, licensing, and manufacture, the transport is a special task requiring great care and a great deal of coordination. The core catcher is transported disassembled from the factory to the port, where it is loaded onto a ship with special attention paid to weight distribution.

The core catcher will arrive in Paks in a few weeks, where it is planned to be permanently installed in the first half of next year.

This is the first major piece of equipment to be completed in the history of the Paks II project, and will soon be followed by other long-life equipment, including the reactor vessel, the heart of the plant, whose production process is similarly being overseen by experts in Paks.

Via Magyar Építők, Featured image: Facebook/Paks II. Atomerőmű Zrt.