The engines currently manufactured at the Győr plant have power outputs ranging from 95 to 150 horsepower.Continue reading

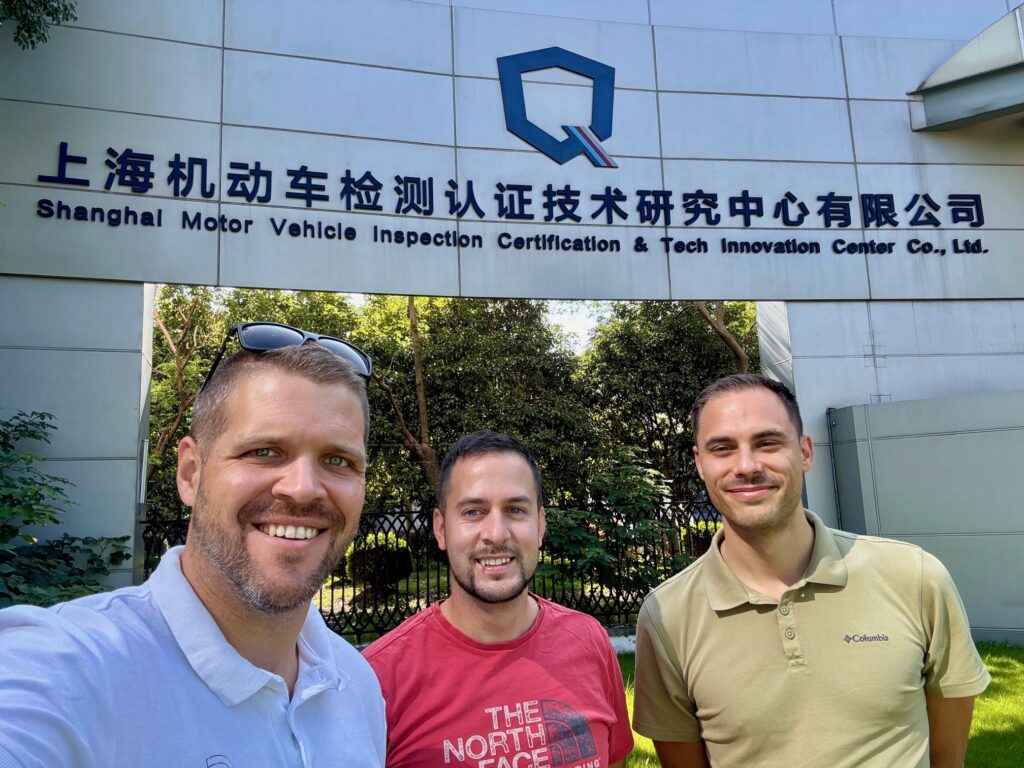

A basic requirement for entering the Chinese car market is compliance with local regulations that can only be verified by official measurements carried out at accredited test centers. Recently, the PPE (Premium Platform Electric) drives manufactured at Audi Hungaria successfully completed this process after three engineers from Győr (western Hungary) validated the performance of the drives at an independent laboratory in Shanghai.

The powertrains used in the Audi Q6 e-tron, A6 e-tron, Porsche Macan, and Cayenne models have already obtained the necessary approvals in several international markets, such as the EU and North America. However, China has one of the world’s most stringent automotive regulations, especially for imported electric drives.

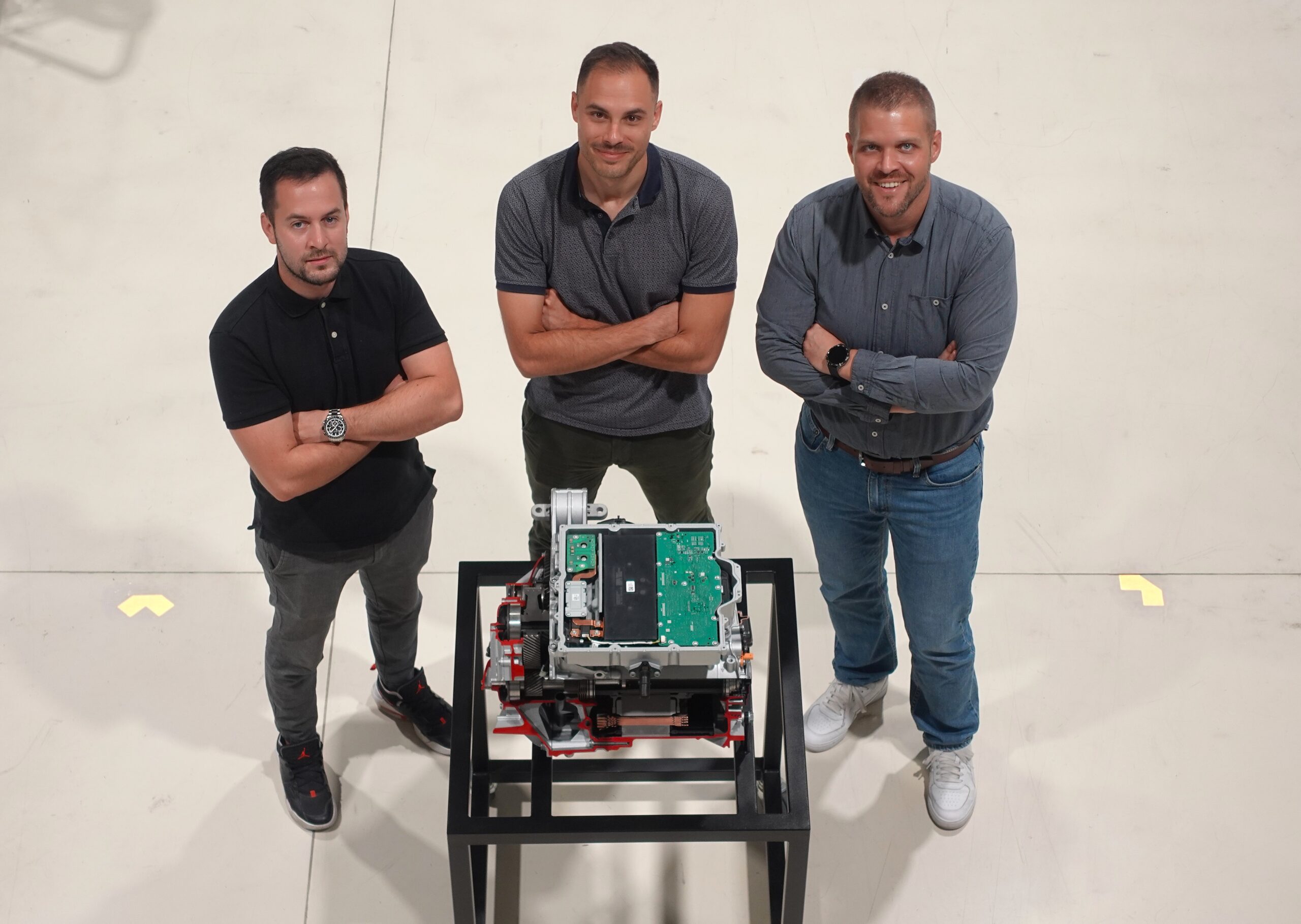

The team of Hungarian engineers conducting the testing – László Kónya, Dávid Hertner, and Tamás Rasovszky – spent a week and a half in Shanghai. Their job was to validate the measurements taken at the Győr site in accordance with Chinese standards. Based on the results of the performance, efficiency, and durability tests, the drives met local regulations, giving them the green light to enter the Chinese market.

The preparation for the tests, i.e. the homologation process, began well before the official inspection, as negotiations with the test center have been ongoing for almost a year. We tried to make the most of our stay there, therefore we prepared, coordinated, and timed everything down to the smallest detail,”

said Kónya, who has been working as an engine development engineer at Audi Hungaria for nine years.

Photo: Audi Hungaria

The three engineers had already measured all the relevant data during testing in Győr, thus they arrived in China well prepared, where they also had to carry out brake pad tests in accordance with Chinese standards.

These included efficiency mapping, speed measurement, functional tests, and even tests against extreme environmental influences such as immersion in water, dust, and salted road surfaces.

The delegation used the services of an external company, ensuring the brake bench adaptation of the drives and assisted them in the operational management of the logistics process. “After all, we had to fly 12 electric drives from Győr to Shanghai and then prepare them for a complex testing process. Our assignment and professional coordination also included preparing for the quick and smooth execution of this on site,” explained Rasovszky.

In addition to their professional tasks, the engineers also encountered cultural differences. Outdoor life is completely digital – cash or bank cards are hardly used anywhere, said Kónya, adding: “Even retired ladies pay with smart watches at the market.”

Photo: Audi Hungaria

Kónya also mentioned how surprised they were by the number of unknown Chinese car brands on the roads, most of which were electric or hybrid. “Walking alongside the divided highway, it was possible to hold a conversation in a normal voice, with only the buzzing of cicadas providing background noise. We did not experience any smog at all. It is astonishing how much electronic gear Chinese cars are equipped with, most of which is not necessarily used by drivers,” he said.

The engineering team’s experience is a good illustration of the complex and international nature of the work behind automotive developments. With the success of the tests carried out in Shanghai, Audi Hungaria has taken an important step towards establishing a presence in the world’s largest car market with its state-of-the-art electric drives manufactured in Győr.

Via Audi.hu, Featured image: Audi Hungaria