BYD, the world’s leading manufacturer of new energy vehicles, announced in 2023 that it would build its first European car plant in Szeged with an investment of several billion euros, capable of producing 300,000 cars per year. Construction of the factory has already begun, and according to preliminary information, production could start in 2025. For this reason alone – and of course out of sheer curiosity – the editorial team of Hungary Today gladly accepted the invitation to visit the Chinese company’s headquarters in Shenzhen.

Photo: Hungary Today

Founded in 2003, BYD Auto is the first car manufacturer in the world to stop producing fossil fuel vehicles as part of the transition to electric mobility. The world’s leading manufacturer of new energy vehicles (NEVs), offering not only electric vehicles but also plug-in hybrids (PHEVs), became the market leader in the battery-electric vehicle (BEV) segment in Hungary in July, August, and September.

Photo: Hungary Today

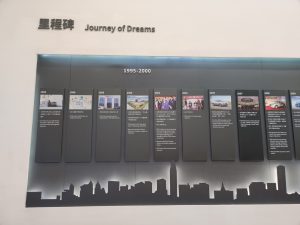

The company’s headquarters in Shenzhen not only has a lot to offer car enthusiasts, but also history buffs. The central building presents, among other things, the history of the company from its foundation to the present day in a museum-like setting. It shows how BYD’s corporate strategy has changed and how the car manufacturer decided to stop producing vehicles powered by fossil fuels. It also introduces the company’s innovation-orientated development concept, the four main brands, and BYD’s global expansion.

Photo: Hungary Today

Photo: Hungary Today

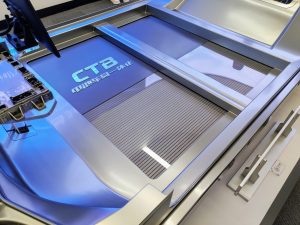

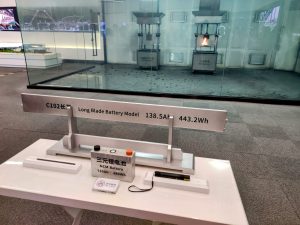

In the showroom, we were able to take a look at the industry-leading Blade Battery, the e-Platform 3.0 floorpan, and the Dual-mode Hybrid Drive (DM-i) technology, which the company is using to accelerate the transition from fossil fuels to electric vehicles.

Photo: Hungary Today

Photo: Hungary Today

BYD has registered over 20,000 patents worldwide, of which over 10,000 are in China. According to BYD, around 100 new patents are filed every day. The company has set itself the goal of having over 100,000 patents by 2025.

Photo: Hungary Today

These patents include the Blade Battery. According to the BYD website, the unique, flattened brick shape of the blade battery increases the efficiency of cooling and preheating. The cells, arranged in blocks next to each other, also serve as structural braces to make the battery more resistant to collisions. The lower and upper parts of the battery pack are made of high-strength aluminum panels with a honeycomb structure, which significantly increase the vertical rigidity. The space utilization of the blade battery is more than 50 percent better than that of conventional batteries, resulting in a higher energy density and greater range. To demonstrate the outstanding safety of the BYD battery, we were shown a needle penetration test with an NCM battery and a blade battery. The blade battery passed the test without catching fire or developing smoke.

Needle penetration test with an NCM battery (back right) and a blade battery (back left). Photo: Hungary Today

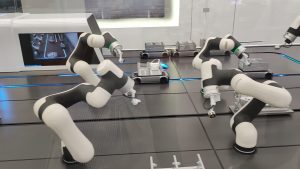

Using models, the operation of the fully automated production lines and the vehicle assembly process were illustrated.

Photo: Hungary Today

Photo: Hungary Today

In addition to the BYD cars, the company’s railway solutions were also presented. The Sky Shuttle, a low-capacity intelligent rail transport system that the company has developed over the past seven years, draws its power from charging stations at stops while passengers board and alight, allowing it to travel to its final destination without having to stop to recharge.

Photo: Hungary Today

Photo: Hungary Today

At the end of the visit, we took a closer look at the BYD models on display. The most eye-catching car in the building was the YangWang U8, which was also unveiled in Hungary two weeks ago. The four wheels of the huge SUV are driven by separate electric motors, which enable precise control of grip and torque transmission in all situations with extremely short reaction times. The fully independent control of the four electric motors also fundamentally changes the maneuvering capabilities: the right and left drive can be reversed so that it can turn like a tank in one position.

BYD YangWang U8. Photo: Hungary Today

BYD YangWang U8. Photo: Hungary Today

With a length of 5,319 millimeters, a width of 2,050 millimeters, a height of 1,930 millimeters, and a net weight of around 3.5 tons, the car is equipped with 1,197 hp. The YangWang U8 accelerates to 100 km/h in 3.6 seconds and reaches an electronically controlled top speed of 200 kilometers per hour. But all this is dwarfed by the U8’s most extreme capability: The SUV, which weighs almost 3.5 tons, is also capable of floating for about half an hour.

BYD YangWang U8. Photo: Hungary Today

BYD YangWang U8. Photo: Hungary Today

Build Your Dreams (BYD), which has 300 dealers in 23 European countries, including Hungary, has launched six all-electric models on the continent: the Atto 3 (compact SUV), the Han (upper mid-class limousine), the Tango (upper mid-class SUV), the Dolphin (compact five-door), the Seal (mid-class limousine), and the Seal U (mid-class SUV).

Photo: Hungary Today

Last week, news broke in the world press that the Chinese government was ‘emulating’ major car manufacturers to stop major investments in countries that voted in favor of imposing tariffs on their products. Beijing has also ‘asked’ CEOs to invest in EU countries that voted against the tariffs. These include Germany, Hungary, Malta, Slovenia, and Slovakia.

This therefore means that BYD’s investment in Hungary, among others, is not jeopardized because the country did not vote in favor of the tariffs on Chinese electric cars.

According to press reports, BYD could even move its European headquarters from the Netherlands to Hungary for cost reasons.

Photo: Hungary Today

Stella Li, top manager of the Chinese electric car market leader BYD, recently announced that the company wants to become an important market player in Europe. BYD’s plan to set up car production in Hungary by the end of 2025, could make an important contribution to this.

Photo: Hungary Today

During our visit to the BYD headquarters, we had the opportunity to ask whether the company plans to collaborate with the University of Szeged in the future, and the answer was a resounding ‘yes.’ Therefore, the Chinese company is also planning to offer Hungarian students the opportunity to build their dreams together. Whatever the fate of the European headquarters will be, it is already clear that Szeged and the automotive industry in Hungary can benefit greatly from the presence of the Chinese giant.

Featured image: Hungary Today