Automation technologies increase production efficiency, helping the company to stay competitive.Continue reading

The Austrian Wienerberger is building one of the most modern concrete roof tile factories in Europe in Hejőpapi (northeastern Hungary). With the HUF 12 billion (EUR 30 million) investment, the company is building a fully automated production line and a carbon-neutral plant, Világgazdaság reports.

In Hejőpapi, a hall with a floor area of 7,300 square meters, production technology using Industry 4.0 solutions, concrete mixing equipment, and a one-hectare outdoor warehouse will also be built, according to the company’s statement. The facility will be the company’s first concrete roof tile production plant in Hungary. The production line will manufacture large concrete roof tiles and other related products.

The predominantly export-oriented, carbon-neutral plant will start production in the second half of 2025, with an annual capacity of three million square meters.

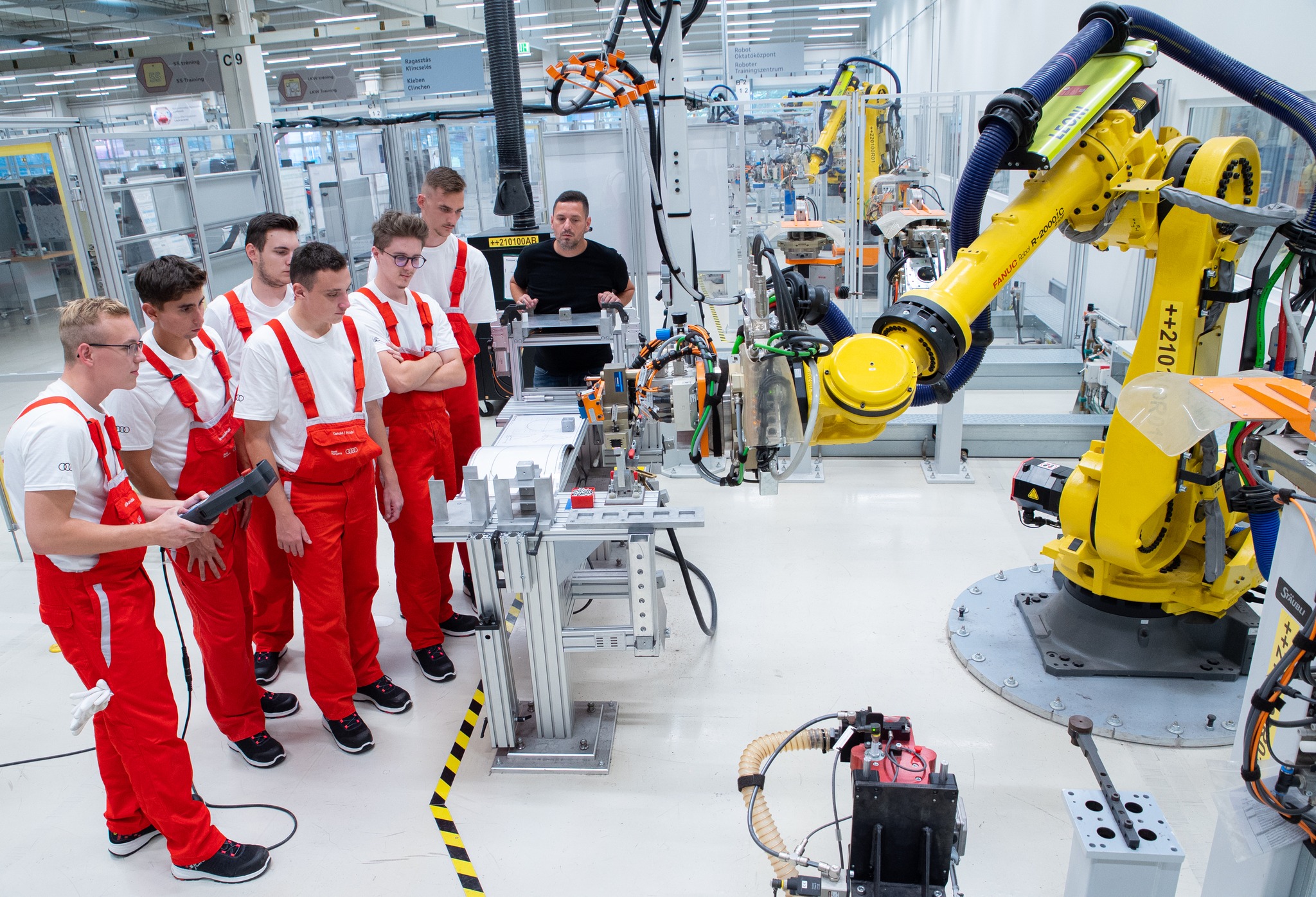

The production of the roof tiles will be fully automated, from the mixing of the concrete to the molding and drying of the tiles and their transfer to forklifts. The finished pieces will be molded by machines, moved by robots, packed and prepared for delivery. Only for some types of components will some processes still be done manually, as they cannot be fully automated.

As the next step in its value-creating growth strategy, wienerberger is investing in the construction of a state-of-the-art Industry 4.0 #productionfacility in Hejőpapi, Hungary, as a driving force for #modernconstruction and #sustainableliving. #worldofwienerberger

— wienerberger (@wienerberger) April 17, 2024

The plant will meet the requirements of Industry 4.0 in terms of automated data collection, transmission, and evaluation. Production will be tracked online throughout the entire factory: production speed, energy consumption, and possible errors. In the future, staff will constantly monitor machines and equipment to ensure the smooth running of the production process.

In addition, the digital outdoor warehouse system developed and successfully operated at the company’s plant in Békéscsaba (southeastern Hungary) will be deployed here, revolutionizing the company’s warehouse management processes. This system greatly improves the traceability and control of stocks and speeds up the packaging process.

Photo: Facebook/Wienerberger Deutschland

The concrete mixer will also automatically clean itself at certain intervals. The resulting wastewater is filtered and reused in the production process, contributing to an environmentally sustainable operation. The resulting production process will be completely CO2 neutral. The building will be heated by a heat pump instead of natural gas.

Wienerberger’s Hungarian subsidiary already operates as a regional production center in several European countries. According to the company, 70 percent of the ceramic roofing tiles produced in Békéscsaba and more than three quarters of the beams produced in Kőszeg (northwestern Hungary) are for export.

Via Világgazdaság, Featured image: Facebook/Wienerberger Magyarország