As for the meat dish: one of the typical staples of Hungarian cuisine, venison, was chosen for the final of the Bocuse d'Or Europe, held in Budapest this year.Continue reading

When the city of Gyula is mentioned, surely the thought of one of our famous hungaricums comes to mind, Gyulai sausage. But in Gyulahús Kft.’s portfolio, Gyulai májas (Gyulai liver sausage) is just as iconic, especially considering that it was the first liver spread served in Hungary. We had the opportunity to observe the production of this delicacy, while also, of course, taking a look at the factories of the Gyula-based company.

Translation by Tamás Vaski

Gyula’s winter market ascended to be among Europe’s largest markets during the 18th and 19th centuries. Some sources say an average of 20-30 thousand pigs were herded to the market, while others write about 100-120 thousand, all being brought to Gyula on foot. During the move, it was possible for an animal’s feet to be injured, in which case they had to be cut off in order to preserve the meat. This is how the need arose for a public slaughterhouse to be built in the city – a need which was met in 1868.

By the end of the 19th century, Gyulai sausage production was in full swing, with many butchers offering up their own products. Among them was József Balog Jr., who brought Gyulai to Europe-wide popularity, winning gold with the sausage at the 1910 Brussels International Exposition. András Stéberl, who worked as the assistant of Balog Jr. Stéberl, connected his experience from abroad to the trade after he learned the forte of sausage making, and initiated the mass production of Gyulai sausage, along with a number of other meat products. This is where the story begins.

Difficult years in the 1990s and the early 2000s forced the Gyula Meat Factory to liquidate in 2012. In February of 2013, however the establishment of Gyulahús Kft. brought the meat production of Gyula to new standards. The company purchased the liquidating Factory’s buildings, machines, and brand name with the help of the municipality’s job retention state support program, effectively saving Gyula’s meat production industry.

Even today, the sale of dry goods follows the original, Stéberl-style of production, with the incorporation of traditional technologies. The preparation of stuffed products – liverwurst, sausage, cold cuts – continues to take place on the Kétegyházi street location, which was renovated in 2010. Product development is uninterrupted in both departments, as it is important for new products to be available for people with allergies as well.

Gyulahús (Gyula Meats) was among the first companies of the 80s which brought this style of spreadable liver sausage onto the market.

Today, the company sells roughly the same amount of liver-based products as it does Gyulai sausage, 2,000-2,000 tons. As such, in 2021, their sales reached 5,600 tons, with a revenue of HUF 8.3 billion (EUR 22.56 million).

Gyulahús aims to connect its sausage and liver sausage production, which currently takes place in two separate locations, since there is incentive for an even greater production capacity of the liver processing department.

Slaughtering does not take place at the production plant, all ingredients are purchased from outside sources, used in producing pâté, and packaged. This is a much more comfortable solution for all parties, and it is most certainly doubtful that any of the locals miss the public slaughterhouse in the city center.

Gyulahús is constantly striving to modernize and to meet the challenges of the current age. Their liver products have always been gluten and lactose free, so there were no reforms required in that area.

Not too long ago, however, the company changed its public appearance, and redesigned the packaging of 90 products, modernizing them. Instead of employing a vacuum seal on sausages, they now use a shielding gas solution which reduces carbon emissions. The thickness of the packaging has also been reduced, and in the case of precut products, a portion of packaging uses recycled components.

The production procedure itself is quite simple. There is a specific recipe (which is classified of course), according to which the ingredients purchased from outside are cooked together. As a first step, quality control measures are taken to ensure the ingredients are up to par.

After this, all the ingredients (liver, fat, rinds-soaked water, and spices) are sent into a 216 kg cooking and grinding machine. This machine handles the bulk of the process, as from here the product is placed into the plastic intestines.

This step is followed by the cooking process, together with the packaging. The meat packages are steamed at 82 degrees Celsius for 70 minutes, than cooled down. finally, the finished product is tested in a lab for safety.

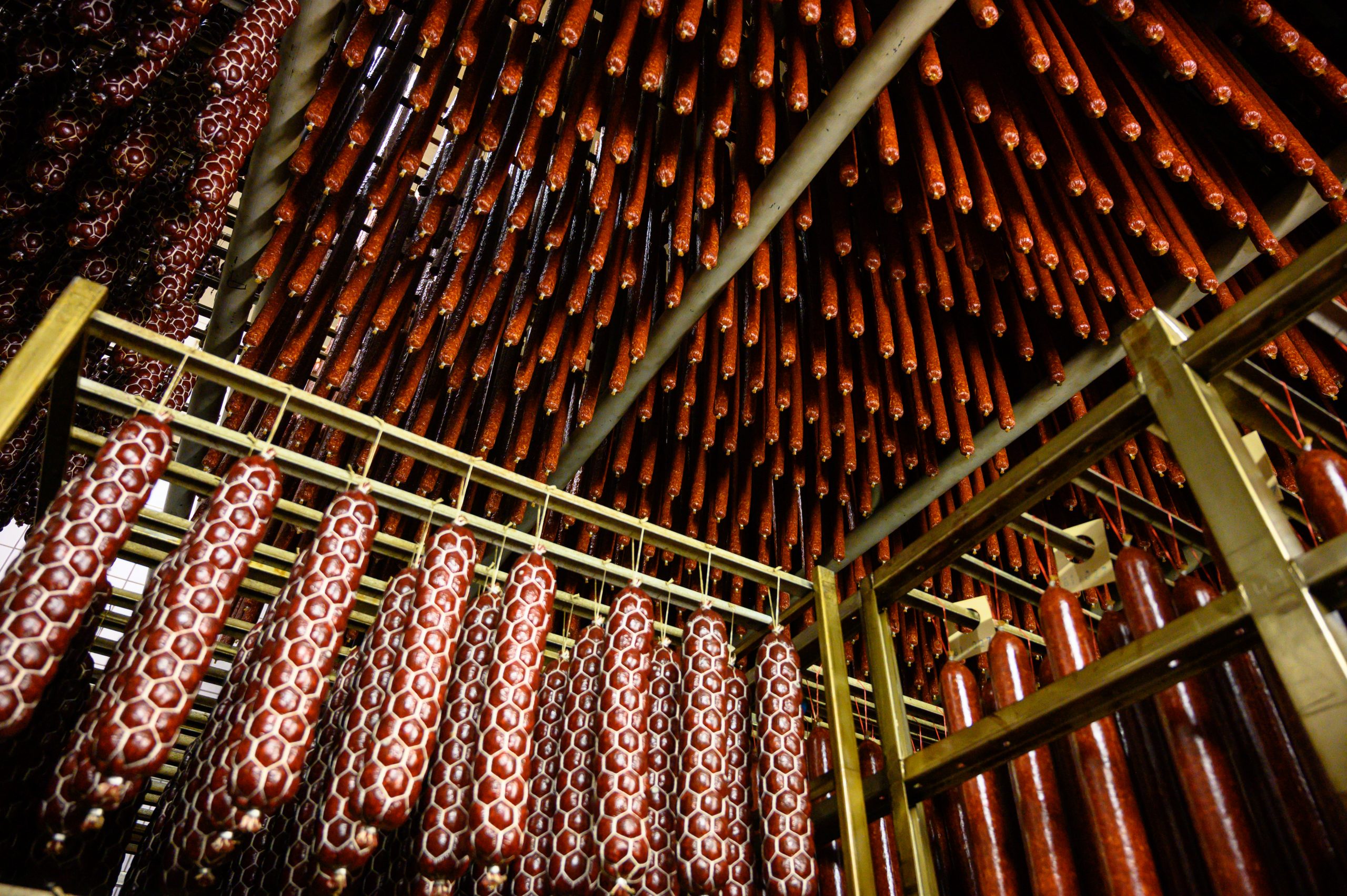

In this media tour which we took part in, our guides focused primarily on the production of liver sausages, but we also had the opportunity to view the sausage aging department as well.

To put it bluntly, it’s not just the walls that are made out of sausages here, but even the ceiling!

And while we’re still on the subject of sausage, here’s one more interesting discovery: Did you know that locals in Gyula can produce Csabai sausage, and locals in Csaba can produce Gyulai sausage?

Gyulai sausage (or Gyulai paired sausage) is a hungaricum with a distinct style of preparation, it only uses Hungarian ingredients and is geographically protected, meaning that it is only produced within the municipal borders of Gyula and Békéscsaba. The most noticeable difference between Gyulai and Csabai is in their thickness. Gyulai sausages are stuffed in the small intestine of the pig and measure between 30-35 mm in thickness upon completion. Csabai sausages are stuffed in the large intestine of the pig, causing their thickness to be uneven, typically between 40-50 mm, but reaching up to 60 mm in some cases.

Another significant difference can be found in the way the two are spiced. Gyulai sausages primarily involve black pepper, while Csabai sausages primarily involve cumin. Both are paprika-based sausages, but Csabai is always spicy, while Gyulai’s intensity can be found in the black pepper it is created with.

Csabai sausage is primarily produced by butchers and their dynasties, while Gyulai has been a factory-based mass-produced sausage since the time of András Stéberl.

Photos and featured photo by Péter Csákvári/Hungary Today